Hi @Dr-Sassi - thanks for taking the time to look at the file!

I hope I am not missing something key in the rig you sent - from what I am seeing, it doesn't look like an approach like this (which I have indeed tried!) will quite get me to where I need to be in terms of accurate IK control of the entire robot arm.

My end goal is to only have to animate the position of the mounting surface of the EOAT (end-of-arm-tool), such that I could draw a straight line without having to animate all the intermediate joints - this is the behavior for actually programming the robot, and I have seen this correctly/accurately "simulated" by a 3rd party robotic simulation software [Visual Components - https://academy.visualcomponents.com/lessons/doosan-robot-connectivity-plugin/ ]

Because all the joints have to coordinate in a non-linear fashion in order to drive the EOAT along a straight line (at any given angle within the working envelope), you'll never really be able to achieve that accurately by manually rotating the joints - even if you save some work by having J1/J2/J3 driven by IK.

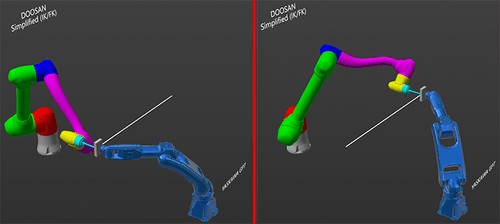

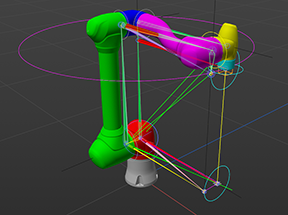

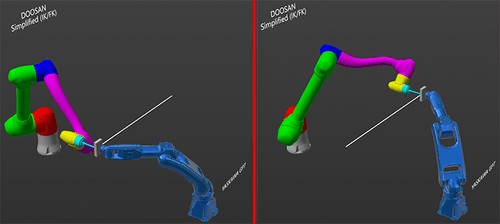

If you look at/click on the image below, hopefully it shows up big enough to illustrate what I am describing: the J4 (lavender) / J5 (yellow) / J6 (cyan) all have to coordinate their rotation if the EOAT is to maintain a locked orientation along a straight line. Even if I could get the positions dead on at either end of the move, the interpolated move in-between will not be along the straight line since a default spline within C4D is not the motion profile necessary on those joints to complete a linear move with the EOAT.

It seems to me that there is some kind of IK feedback loop which I am unable to replicate, because the IK-solution for J1/J2/J3 depends on the location of J4/J5/J6, but their orientation depends on the orientation of J1/J2/J3 ... so I have been chasing my tail! Part of my trouble is that I cannot seem to "push" anything with IK ... it is always a "follow-along" setup.

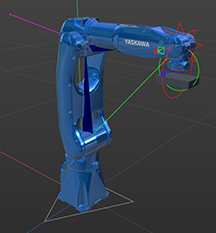

The blue robot is the YASKAWA GP7 I referenced earlier, which I did successfully rig up do this - I simply animated the position / rotation of the EOAT, and the intermediate 6-axes followed along beautifully based on IK and up constraints - but the catch is that here all the joints are in the same plane; the DOOSAN joints are all in slightly offset planes such that my method for the GP7 hasn't been working this time.

I hope that all makes sense! Again, thank you for taking the time to look at it. I can upload the file which is in the screenshot above, if that would be helpful - just send send me another Dropbox link.

Thanks!

~MV